Description

Driver Engineering: Optimizing AFDS for D7000

As one of the top headphone manufacturers in Japan, Final has extremely deep technology for driver development. When reviewing the complete design of the new Final D7000 headphone, they reduced the weight significantly compared to the D8000 (Pro) from the diaphragm, all the way to the chassis, headband and ear pads.

In the past, with the development of the “Air Film Damping System, AFDS” Final has made comprehensive improvements to the structure of flat-panel units in order to enhance the sense of low-frequency volume and space of flat-panel headphones. In short, by adding a metal perforated plate between the magnet and the diaphragm, the internal airflow of the unit operation is used to drive the diaphragm, so that the diaphragm will not collide with the magnet and affect the sound. The AFDS design benefits the tensioning of the diaphragm making the low-frequency volume feel deeper and more natural.

For the D7000 Final has redesigned the “Air Film Damping System. The original dual-magnetic structure which is used in the D8000 and D8000 Pro has been changed for this headphone to a single-magnetic structure and performs push-pull actions at the same time. Therefore, the diaphragm has a larger activity space, and the amplitude of the diaphragm becomes larger, which can effectively create a more powerful low-frequency response and a sense of space.

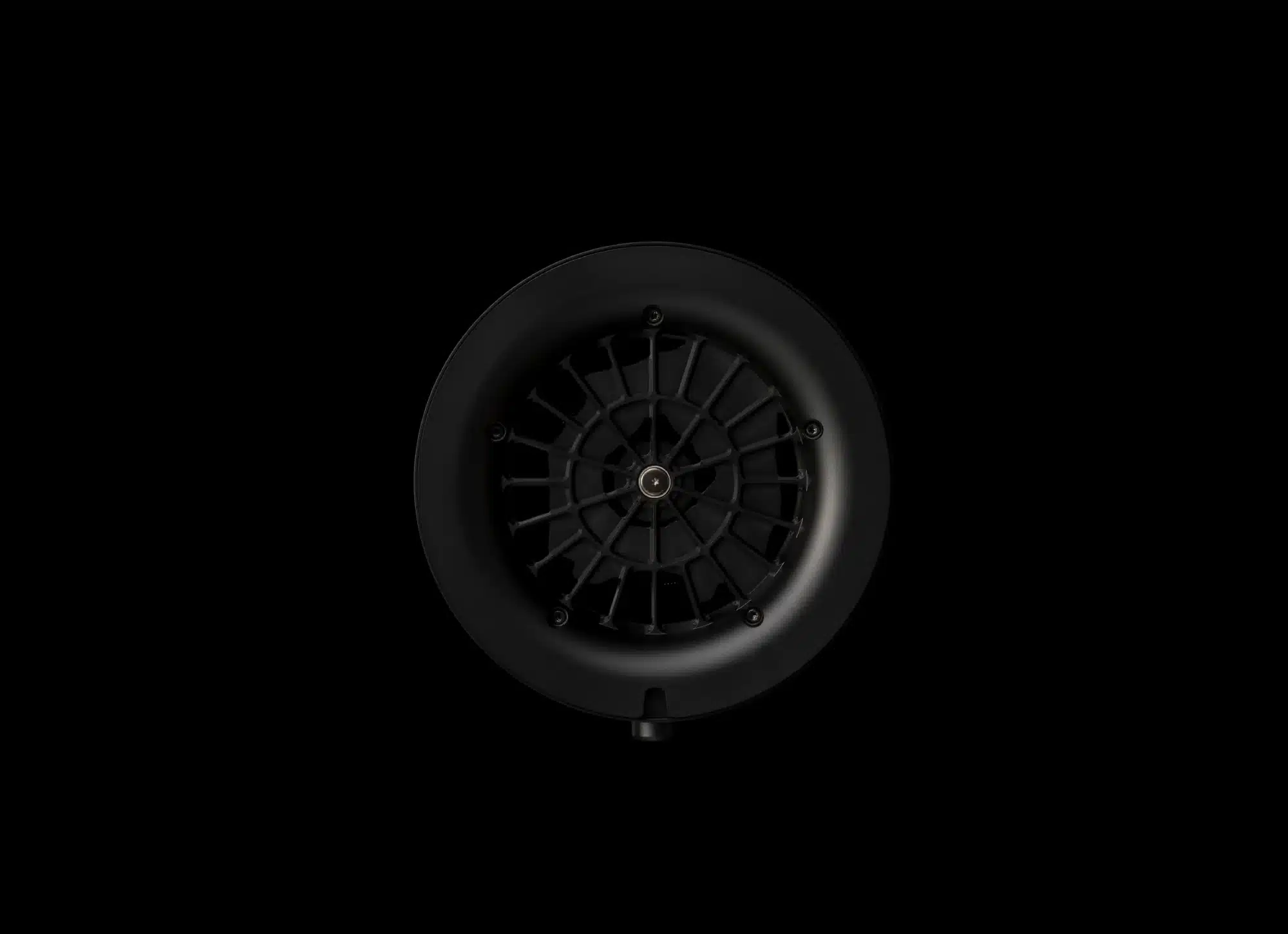

Pinna-align Diffuser

In the D7000 Final has incorporated the concept of acoustic adjustment using diffusion, which is becoming standard in professional recording studios with the latest acoustic design. In the early development of the D8000 the engineering team had already the idea to incorporate a diffuser. Under ideal conditions it yielded great results, however they stumbled upon various difficulties as the shape of the outer ear (pinna) differs from person to person. This results in large differences in the perceived sound quality. To solve this issue they repeatedly conducted simulations and actual hearing experiments that matched various outer ear shapes, and finally arrived at the shape of the diffuser that was optimal for every user. This Pinna-align diffuser is now added to the earcup design of the Final D7000.

Newly-developed open type earpads

Most headphones, both closed-back and opened-back headphones, have sealed earpads in order to extend the reproduction frequency to the low-end to compensate for the lack of bass reproduction of the driver unit. In order to create high-quality bass, the driver unit itself must be capable of reproducing those low frequencies and should be paired with more open earpads.

Final D-series headphones already have the extension of the bass frequencies through AFDS, so it has become possible to sufficiently reproduce bass frequencies even with earpads that are not sealed tightly. For the D7000 Final has made ear pads made from a special fabric made from Japanese paper that is both dry to the touch and durable, achieving high durability with antibacterial/odor-eliminating properties.

Produced in Kawasaki in pursuit of precision

The D series is manufactured at Final’s headquarters in Kawasaki. The accuracy of product assembly depends not only on the accuracy of the parts, but also on the accuracy of the jigs that assist in assembly. We design and manufacture production jigs in-house so that slight variations in component precision can be fine-tuned during assembly.